Design and construction of frame baths with an attic. Do-it-yourself frame bath: step-by-step construction instructions Video: do-it-yourself frame baths from foundation to roof

Frame house construction technology is widely used for bathhouses, garages, sheds and other outbuildings. Frame bathhouse projects (6x6, 3x4) are warm and durable buildings, and the speed of their construction is such that you can take a steam bath within 2-3 weeks after the start of construction. And, of course, the low cost of materials and work process leaves no one indifferent when planning real estate on the site.

Typical drawings of a 6x4 bath

Examples of individual projects of frame one-story baths

Below you see individual project frame bathhouse 6x4 m, which shows that in addition to a steam room with an area of 7.65 m2, the building has big room for relaxation, a compact bathroom and a vestibule with a porch. The frame stands on a strip shallow foundation (MZLF) with a depth of 0.7 m, the foundation has a continuation in the form of a plinth 0.4 m high, the total height of the MZLF is 1.1 m, the layer of crushed stone or gravel under the base of the foundation is 0.2 m. Tambour does not allow cold air masses to penetrate inside when the doors are opened.

A simple drawing of a bathhouse measuring 4x6 m

A simple drawing of a bathhouse measuring 4x6 m Total area – 24 m2, room dimensions:

- Recreation room – 12 m2.

- Steam room for 7.65 m2.

- Bathroom – 4.35 m2.

What building materials is the frame made from?

- Vertical posts, upper and lower strapping – board 100 x 50 mm.

- Subfloor beams – board 150 x 50 mm.

- Rafters – board 150 x 50 mm.

This project involves a heater installed and heated in a steam room, and such a close arrangement is due solely to size. A parallel option for the location of the stove is also in the steam room, but with an elongated combustion chamber, which will allow you to lay firewood from the rest room. This solution will allow you to heat not only the steam room, but also the relaxation room.

Bathhouse project with attic

Standard design solutions (6x6, 3x4, 5x4, etc.) are unlikely to offer a frame bathhouse project with an attic. This is a purely private solution due to its small size land plot and the desire to place as much as possible on it usable areas. The lower floor has a standard set of premises: a relaxation room, a steam room, a terrace, a sink, a dressing room (in the project drawing there is an entrance hall) and, of course, an attic floor.

Drawings of a 6x4 bath with an attic

Drawings of a 6x4 bath with an attic

Such a 6x4 frame bath is also quite cramped, but the attic expands its capabilities. In addition, the size of the structure allows the use of standard 300 or 600 cm long lumber, which minimizes waste. The bathhouse can be placed on a columnar, strip or pile foundation, since its weight is insignificant due to the frame version of the frame.

The project is more functional, since after the steam room you can not only relax in a separate room, but also simply take a shower in the washing room. The steam room is connected to the washing room by a separate door, so the temperature and humidity in the shower room will be quite high. In addition, you can arrange a couple of beds in the washing room, which will further increase the comfort of relaxation after the steam room.

The total area of this project including the attic is 42 m2. Dimensions and area of premises:

- Rest room – 10 m2.

- Hallway – 2.25 m2.

- Washing room – 3 m2.

- Steam room – 5 m2.

- Attic – 18 m2.

Bathhouse project with terrace

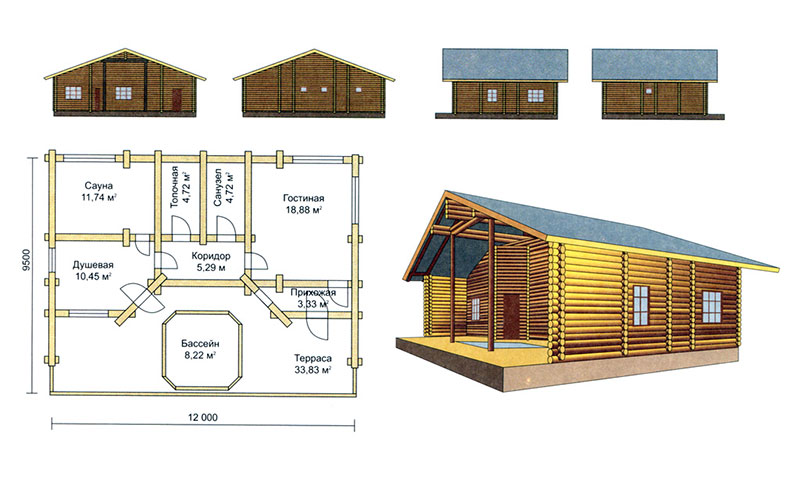

Typical designs of frame baths (6x6, 3x4, 5x4, etc.) with a terrace (examples can be downloaded for free in the public domain) most often simply divide the total area in half, leaving little space for functional rooms. Therefore, custom design is preferable in this case, and one solution is shown below. The bathhouse is quite spacious (114 m2), since with dimensions of 6x4 it is very difficult to arrange a terrace.

They try to equip similar projects (can be downloaded online for free) with wider capabilities, since additional space allows this to be done. Thus, the drawings of this project show the presence of a swimming pool combined with a steam room and a corridor, as well as a sauna and a separate heating room, a living room and, of course, a spacious terrace, which is pleasant to go out onto. There are plenty of photos of similar finished buildings on the Internet.

Since the combustion chamber is fenced off from the rest, it is possible to install not just a heater in it, but also equip a small heating system covering those rooms that are not heated by the steam room. Since there are many such rooms, heating will not be superfluous, especially for a winter terrace. According to the diagram of this project (a more detailed one can be downloaded for free on the Internet), the terrace is specifically intended for winter use, so it is separated by an entrance hall and a corridor, which also need to be connected to the heating system.

Even frame baths with a terrace can be easily erected with your own hands, without the involvement of special equipment and workers.

The total area of the bathhouse built according to the photo above is 114 m2. Area and dimensions of premises:

- Sauna – 11.74 m2.

- Shower room – 10.45 m2.

- Steam room with swimming pool – 8.22 m2.

- Terrace – 33.83 m2.

- Entrance hall (dressing room) – 3.33 m2.

- Corridor – 5.29 m2.

- Furnace room – 4.72 m2.

- Bathroom – 4.72 m2.

- Living room (rest room) – 18.88 m2.

Building materials:

- The strapping is timber 100x150 mm.

- Rafter system – board 100x50 mm.

Small bathhouse with terrace

The dimensions of this mini-bath are 4x4 m, the dimensions of the terrace are 4x1.5 m. For a family of 3-4 people, these are quite acceptable dimensions. Functionality does not suffer from size - there is a sink, a steam room for two people, a relaxation room, while there is enough space left for a veranda or terrace, wet areas windows with vents are equipped (one in the steam room, one in the washing room).

The steam room is ideal for one person, since there is only a lying shelf; on the second one you can only sit, which in the concept of a Russian bath is not quite a complete rest (Finnish ones do not count). The size of the washing room is not critical, since there will always be only one person in it. Therefore, the area of the washing room is sacrificed to the size of the terrace and rest room.

Area of all premises with calculation:

- Recreation room – 5.67 m2.

- Sink – 3.04 m2.

- Steam room – 3.61 m2.

- Terrace – 6 m2.

Construction Materials:

- Strapping beam – 100x150 mm.

- The subfloor is timber 150x100 mm.

- The ceiling is covered with boards 150x40 mm.

- Rafters - edged board with a section of 100x50 mm.

- Roofing materials – corrugated sheets, galvanized sheet metal, metal tiles, slate, ondulin.

Frame bathhouse 5x6 m

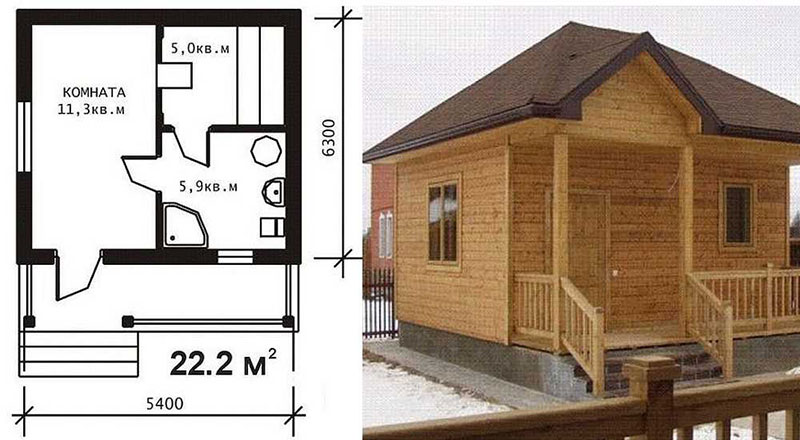

All frame baths, the projects of which are presented here, as well as Finnish ones, are designed for DIY construction with minimal labor and financial costs. For example, the plan presented below is simplified to the minimum and this attracts home owners who want to be able to take a steam bath even in a small area. But even such a small building can be equipped with an extension - a terrace measuring 2x5.4 m, along the length of the short side of the bathhouse.  Photo and drawing of a bathhouse with minimal functionality

Photo and drawing of a bathhouse with minimal functionality

Options:

- Total area – 22.2 m2.

- Steam room – 5.0 m2.

- The area of the rest room is 11.3 m2.

- Washing room – 5.9 m2.

- Terrace – 10.8 m2.

Advantages of building baths on a frame basis

Frame design includes a timber frame covered with finishing lumber inside and out. All free space inside the frame is filled with layers of vapor and heat insulation. This form of construction is ideal for private developers, because it automatically falls into the low-budget category. In addition, construction can be made even cheaper if you use not industrial materials for thermal insulation, but folk insulation techniques using shavings, sawdust, etc.

Due to the low weight of the structure there are additional advantages. Thus, the foundation on which the frame bathhouse will stand (the projects described above) can be built lightweight - shallow or shallow, piled or columnar, which is very cheap compared to foundations of other types and capacities. Of course, if the developer wants to play it safe, then the building will work fine on both a slab and strip monolithic foundation, but the cost of the project will increase significantly.  Wall diagram

Wall diagram

During construction you will need a set of standard garden tools: saw or hacksaw (can be replaced with a grinder), hammer, wood screws or nails, screwdriver or powerful screwdrivers, plumb line and building level. If it is possible to mechanize the construction process, the final result will only get closer. The main advantage of construction is that even one person can do this work with his own hands, which means saving the family budget.

Flaws

High fire hazard is the main disadvantage of a bathhouse, which is partially minimized by impregnating the wood with fire-retardant solutions. Due to the increased fire hazard, electrical wiring must be laid in a self-extinguishing corrugated hose, which will make the estimate somewhat larger.  Photo of the “skeleton” of the bathhouse

Photo of the “skeleton” of the bathhouse

Constant high humidity in the premises also has a negative impact on the construction, therefore, in addition to fire retardants, the wood is also impregnated with antiseptics, which cut off the possibility of mold and other fungal diseases. In addition to antiseptic protection, layers of vapor and waterproofing are laid in the space of the frame.

We all love to spend summer weekends in nature. Some simply go out of town to a reservoir, others go to the country. But what is a vacation at the dacha without a bathhouse and barbecue? For those who have recently purchased a summer cottage and have not yet decided what kind of building will be located there, we offer best option– frame bathhouse with attic. The advantage of such a structure in small summer cottages is as follows:

- By building a bathhouse with an attic floor, you get a “2 in 1” structure, where you can take a steam bath and spend the night.

- If further construction is planned big house, then such a bathhouse will serve as a guest house.

- During the construction of a good country cottage you don’t have to resolve issues with the temporary shed (change house).

- If the area is small and capital construction you don’t plan on it, a bathhouse with an attic - perfect option to save space for beds and a recreation area, because you don’t have to carve out space for two separate buildings.

Advantages of frame technology:

- efficiency, both during construction and during operation

- easy and quick to install with your own hands

- frame bath does not require shrinkage

- can be built at any time of the year

- wide choose finishing materials

The appearance and layout of a frame bathhouse is practically no different from a bathhouse made of timber (logs). Projects for frame buildings also include a vestibule, a washing room, a steam room and a bathroom, and in the attic, as a rule, there is a recreation room that you can use at your discretion. However, there are differences between them that make frame projects stand out against the background of their log counterparts:

- a frame bath is much cheaper than exactly the same one, but made of logs or timber (you can save even more if you do everything yourself)

- Unlike a log house, which cracks over time under the influence of external factors, the lining of a frame bathhouse made from a block house retains its original appearance

- It takes much less time to build a frame bath

- in the steam room, the frame design provides for upholstery with aspen lining, which perfectly withstands any temperature and creates a useful microclimate

- Non-flammable materials are used for thermal insulation, which allows frame baths to retain heat perfectly

Where to begin

It all starts with a project that you can buy, order from an architect, or create yourself, describing in detail how to build everything yourself - the choice is yours. Typically, projects of any buildings contain the following main points:

- total area

- detailed location of premises

- type of floors

- communications

- Construction Materials

Let's start construction

If the area of the plot allows, then the most optimal project would be 6x6 m. - it will perfectly accommodate all the necessary premises, in addition, the above-mentioned dimensions will make them quite spacious and comfortable. If possible, choose a site for construction that is level, and if this is not found, then try to level the existing territory as much as possible. When the project is ready, you can begin building a bathhouse using frame technology. Next, you can familiarize yourself with one of the many DIY bathhouse projects.

Foundation

For frame structure quite suitable strip foundation:

- remove the fertile soil layer

- we dig a trench and lay a cushion of sand, crushed stone and gravel in it (you can use ASG)

- fill everything with molten bitumen and lay the concrete in a pre-installed formwork made of boards

Before building the frame

- As soon as the foundation hardens, we lay a layer of roofing felt on it, which will serve as waterproofing, and make the bottom frame of the structure. For this we use timber 150x100 or 150x150 mm.

- We connect the joints with nails.

- We install logs made from 150x50 mm boards on the harness.

- We treat the harness and joists with an antiseptic according to the instructions and leave until completely dry.

Frame

From 150x50 mm boards we make frame posts and rafter system parts (everything is done in accordance with the project).

We build walls

- We install two racks in the corners, and several intermediate ones between them

- we install the sheathing (in our case, these are OSB boards) - we fasten the boards to the frame with self-tapping screws (using a screwdriver when doing the work yourself will significantly save time and effort)

- do not forget to periodically check the position of the sheets with a building level

- Simultaneously with the installation of the slabs, we install subsequent racks to which the sheathing will also be attached

So, by installing the racks and attaching OSB sheets to them, we install our entire frame structure (do not forget about door and window openings).

Installing the roof

- According to the project we collect truss structure on the ground;

- We lift the finished structure and attach it to the frame racks.

- To make the work more convenient, we attach a temporary ceiling to the beams. We apply markings for attaching the sheathing for the gable of the building.

Do not forget that all wood that we use for construction must be well dried and treated with fire protection. This is necessary so that the house is not eaten by bugs, which is especially important in houses located in close proximity to the forest.

- between the counter beam and the rafters we lay a layer of special film for ventilation

- We attach the roof sheathing directly to the rafters, then we install the roof

- When the installation of the roofing material is completed, we attach OSB sheets to the gables of the building

Interior and exterior decoration

- We insert windows and doors into the openings and begin interior decoration.

- To arrange the ceiling, you can use the same OSB boards - we attach them to the beams from below.

- We insulate the ceiling and walls with a layer of insulation; in addition to the insulation, we lay a layer of “screen” foil into the walls of the steam room. Glassine is mounted on top of the insulation.

To arrange the floor, we use boards left over from the temporary ceiling when installing the roof (we remove the boards from the beams and nail them to the joists).

Typically, steam rooms in baths are equipped with a stove-stove, and boilers for heating water are installed in the dressing room near the common wall with the steam room (the wall between the steam room and the relaxation room must be brick - this is required by fire safety standards). You can use ordinary building bricks.

In principle, the exterior finishing can be done simultaneously with the interior. This approach will significantly save your energy and time. The frames of internal partitions can be made during construction and materials can be immediately attached to them final finishing(this can be either a block house or a clapboard).

As for the interior decoration, it all depends on the purpose of the room. So, for a rest room you can use a block house, and for other rooms - wooden lining. Exit to the attic can be arranged in the dressing room by making a hatch in the ceiling and installing a ladder.

The ceiling in the steam room must be additionally insulated and lined with clapboard. If you decide to draw up a project and build a bathhouse with your own hands, you should consider that additional insulation The ceiling of the steam room significantly reduces the ceiling height. According to standards, the ceiling height should not be less than 2.1 m.

Timing of installation and all work

A team of three builders usually takes ten days to build a frame bathhouse. If you have assistants and you decide to do everything yourself, without resorting to the help of hired workers, then this approximate plan will help you:

- laying and arrangement of the foundation – 3 days;

- installation of strapping and logs – 3 days;

- construction of the rafter system – 2 days;

- installation of doors, windows, installation roofing materials and work on internal and exterior decoration- 2 days.

Note: you should not strive to strictly adhere to the deadlines given in the plan. The main thing is attention and accuracy - only in this case you will get a good result, and a bathhouse built with your own hands will become a source of pride for you and your family.

More information about the construction of frame baths. About how to build frame house with a bath - read. Everything about panel baths and their construction is in the article.

Good luck!

Frame baths 6x8, 6x4 and similar structures are widely used, not only in regions with mild climates, but also in places with harsh weather conditions.

Briefly, the technology for constructing such houses includes the following stages:

- Laying the foundation;

- Frame assembly;

- Sheathing assembled frame OSB boards or boards on the outside;

- Installation of thermal insulation materials into wall cavities;

- Indoor finishing work (cladding walls, ceilings and floors with boards);

- Finishing work on the facade of the building.

Design Features

Having reviewed the list of works, we see that a 6 by 6 frame bathhouse or an object similar in its characteristics can be built with your own hands without the involvement of highly qualified specialists.

But there is one important point, if you are interested in a strong and durable building, it will be necessary to develop an appropriate project.

Project development

A professionally designed 6x4 frame bath project guarantees whole line benefits, including:

- Ensuring a long service life thanks to a professional approach to calculating the design loads on the frame;

- The ability to select the right type of building materials in accordance with the loads placed on the frame;

- The ability to correctly draw up estimates and, as a result, prevent overexpenditure of building materials;

- No difficulties when registering a construction project with the cadastral authorities;

- A higher price when selling a house along with a bathhouse on the secondary real estate market.

From the above it follows that a 6x6 or 6x4 frame bath project is necessary. But if construction can be done independently, then the development and production of project documentation requires a professional and qualified approach.

You can order bathhouse designs of various configurations from specialized bureaus. You can also obtain design documentation by purchasing a ready-made frame bath kit. As a result, according to the provided plan, you assemble the structure yourself or with the help of invited installers.

In accordance with standard design documentation, the frame for a quick-assembled bathhouse is built in increments of 95-100 cm. A 150x50 mm board or timber is used as the main building material.

Important: If the procurement of materials and construction is carried out independently, you must make sure that the purchased wood is properly dried. If the moisture content of the timber and boards is more than 20%, there is a possibility that the building will “perform” during operation and will require expensive repairs.

A 6x6 frame bathhouse with an attic, as well as a 6x4 building, is built with a steam room and a washing room on the ground floor. A dressing room or changing room is located on the same floor. For greater comfort and safety, the stove-heater is heated not from the washing compartment, but from the dressing room.

According to the project, you can get into the attic from the dressing room through the internal wooden stairs. The calculation of the premises is made in accordance with the planned number of people using the bathhouse at the same time. A number of developers, in addition to the recreation room, provide a terrace or veranda in the attic.

Baths, in accordance with the drawing documentation, are equipped with internal partitions between the washing compartment, steam room and dressing room. Partitions, like load-bearing walls, are made frame + with insulation laid between the layers of the outer covering. The insulation must be laid on both sides with hydro- and vapor barrier film.

Small-sized frame buildings, regardless of the type of finishing materials used, are characterized low load on the ground. Therefore, quick-assembled.

Application strip base guarantees such advantages as saving building materials and time.

Important: organizations involved in the design and construction of prefabricated buildings can, if necessary, make the required changes to the site plan. Of course, making changes to the project will affect its cost, but in this case it will be possible to build a non-standard bathhouse that will best suit your needs.

Assembly technology

Having drawn up a drawing of the bathhouse and decided on its location, you can proceed to the procurement of materials and construction ().

We will need:

- standard boards (50x120 mm);

- timber (120x120);

- bars and boards for sheathing (20-30 mm);

- bars (75x40);

- lining or siding for wall cladding;

- cement;

- roofing felt or roofing felt;

- mineral wool;

- expanded clay;

- fastening materials.

The construction instructions are as follows:

- The site is cleared and marked for construction;

- Along the perimeter, according to the project, a strip foundation is laid under load-bearing walls and partitions;

- The frame is assembled from four frames assembled from bars, transfers and rafters.

- The frames are mounted to the lower frame;

Important: before proceeding to the next steps, you need to saturate the entire structure with antiseptics and fire retardants.

- wall elements are mounted on the prepared frame, which are attached to the frame with anchor bolts;

- the joints formed between the frame and the slabs are insulated with polyurethane foam;

- beams of the rafter system are mounted on top of the frame, and the sheathing is made;

- slabs are attached to the sheathing, on top of which the thermal insulation material;

- on rafter system roofing material is laid;

- then internal partitions are assembled and installed;

- the partition to which the stove will be adjacent is made of heat-resistant brick;

- after the walls are ready, it is carried out interior decoration, during which thermal insulation material and vapor barrier are laid in the walls and partitions;

- further, the space under the floor is filled with expanded clay and covered with a vapor barrier film;

- At the next stage, the finishing floor is laid.

Once the main structure is assembled, you can begin arranging the interior.

Conclusion

Construction of a frame bath from ready-made kits is not difficult if you have a project, the necessary tools and assistants with experience installation work ().

You will find more useful information by watching the video in this article.

If there suburban area with a cottage and relatives or friends often come, small sauna 6x6 with an attic will provide excellent washing and will replace a guest house.

Sometimes we are irresistibly drawn to the sea, to plunge into the azure wave, and sometimes for some reason we would give everything to take a good steam in a real Russian bathhouse. Such a building can be like summer cottage, occupying a small space on 6 acres, and among many other farm buildings. At the same time, it is not at all necessary to build a large complex similar to Roman baths; it is quite enough if it is. Why is the presence of a living room considered in the under-roof space? It’s simple - if there is no cottage at the dacha, such an addition will become quite comfortable housing.

However, you can come up with many uses for an attic even if you have a completely landscaped suburban area with a good-quality house. In particular, in winter, being well steamed, you are unlikely to want to return to the house, even if not through snowdrifts, but along neatly swept paths. Therefore in attic you can pre-arrange one or even two cozy rooms With small kitchen and a bathroom where you can have a good night's sleep. In extreme cases, these premises will replace the guest house. If you already have one, think about placing a billiard room at the top, combined with a recreation room, devoting the area below to the most necessary rooms.

The classic steam room has long been a small building made of logs with a dressing room. As a rule, brooms and tubs were stored in the attic. Today, not much has changed structurally, however, not everyone knows how to steam with a birch broom, and therefore they prefer washcloths with soap, which is also not bad after warming up in the steam room. However, the baths themselves today are often built not from solid logs or even timber, but from ceramic or silicate bricks, or cinder blocks. However, there is an option that for many will be a golden mean - a 6x6 frame bathhouse with an attic will replace a log house with a steam room, which is much more difficult to build.

Let's compare the advantages and disadvantages of both types of construction. Let's start with a frame made of resinous wood. First of all, such a bath can easily withstand the effects of steam, which settles as a wet film on the walls. Among other things, logs, as well as beams, “breathe,” or, in other words, allow air to pass through, so it is always easier to breathe in such a building. As for thermal insulation, it is still necessary to insulate the attic, since the thickness of the log, even with well-caulked joints between the crowns, is still not enough to protect against winter frosts. Yes, and the steam room does not fit under internal lining insulate to make heating faster and cheaper.

A frame bathhouse is advantageous, first of all, in the speed of construction, since it does not shrink, unlike a log house, which means you do not need to wait a year and a half until the crowns completely settle down. And it’s much easier to build a frame; even one person can handle it small design, while no one can move logs alone. In addition, a complete building kit costs much less than rounded lumber, and if you build it yourself, this is a direct savings. As for durability and reliability, if assembled correctly, a 6 by 6 frame bathhouse with an attic will last no less than a log building, and will be much warmer.

Since space is limited, we will consider everything possible options. Let's start with the dressing room, which is absolutely impossible without it, it plays the role of both the entryway and, often, the locker room, and the restroom can be fenced off in the same room. It is also convenient to place the staircase to the attic floor, where it would also be useful to make a small vestibule if there are at least two rooms. In the event that the rest room is upstairs, the entire lower floor should be allocated for rooms, without which the bathhouse cannot do.

Let's say that immediately after the dressing room there will be a washing room, in which it is best to install a shower stall with a deep tray, equipped with the latest technology. You can, of course, make a small pool, or install a home alternative - a jacuzzi. Further, if all the rooms are one after the other, the “enfilade” of rooms will be completed by a steam room, in which several tiers of shelves can accommodate up to six people. With this layout, it is more appropriate to place the stove portal in the washing room, using a small cabinet for storing firewood or coal if the firebox is not gas.

A different layout of a 6x6 bathhouse with an attic is possible, when the rooms are in two rows, for example, opposite front door from the corner dressing room there is an entrance to the rest room, and on the side two doors lead to the toilet in the adjacent corner of the building and the washing room. Next, we traditionally move from the washing room to the steam room, but in this case it is more logical to place the stove door in the rest room, in which there will be and. Here, by analogy with the living room, you can arrange a kitchen, and the attic floor will be divided into a couple of bedrooms and a toilet.

As a rule, instructions are always included in the set of load-bearing elements, but before purchasing it, you should know what you will encounter. That is why it is further proposed short description stages of work. Despite the fact that any construction begins with a foundation, we will omit pouring the base, since a 6 by 6 meter bathhouse with an attic can be installed on anything: monolithic, strip or columnar. The main thing is to prepare an ideal horizontal platform, which can be done using a level. If clayey or sandy soil saturated with moisture, better to use screw piles, which do not require leveling the building site.

Before installing the frame, waterproofing is laid on the foundation, and a strapping board is laid on it, which is fastened with wedge anchor bolts in increments of no more than 60 centimeters. Before final fixation, it is necessary to check the accuracy of the geometry of the strapping belt in accordance with the design plan using a tape measure. A flax-jute cloth of identical width is laid on the strapping (we fasten it with the staples of a furniture stapler), and on top of it, the wall panels are fastened with 6x80 plumbing bolts, screwed every 30 centimeters in a checkerboard pattern, starting from the corner. We fix the first frame element in a vertical position with temporary struts. Between the panels, connected by the same plumbing bolts with the above pitch, strips of flax-jute fabric are laid.

The basic rule for assembling a frame: ordinary Wall panel It is first attached to the adjacent one (at the beginning of work - to the corner one) with preliminary fixation with three clamps, and only then is screwed to the harness.

To prevent wall distortions, struts are installed every two or three panels. Upon completion of the installation of the side panels, a strip of flax-jute cloth is again laid on top of them (shot with the staples of a furniture stapler), onto which the upper strapping board is attached. We make sure to check everything for compliance with the geometry and design plan. Then, after preliminary marking, we begin to fasten with reinforced steel corners and profiles roof trusses, starting from the pediment, fixing them with struts. Floor beams are installed in the gaps.

A good bathhouse is not only a source of physical health, but also improves the morale of visitors. This is facilitated by interior design premises, well-designed room designs and the use of modern building materials.

The first projects of bathhouses with an attic were created for wooden houses. Eco-friendly material has a considerable number of advantages. Nowadays, projects of frame baths with an attic or a project of a bath with an attic and a terrace made of brick or foam blocks are also popular.

The relevance of the construction of the building

A bathhouse with an attic and a veranda, the projects of which are presented on our website, allows you to significantly save space on your personal plot. The presence of a second floor allows you to add additional space, which you can use at your discretion. Therefore, these buildings are relevant for those who have a significant shortage of space.

Most often, the room is used as a guest room, a relaxation area, a billiard room, or sports equipment is placed in it. Even construction companies include in the list of their proposals projects of log baths with an attic. They are offered in several standardized versions.

When drawing up your own project for a bathhouse made of timber or brick with an attic, you should pay attention to some factors:

- often a 6x6 bathhouse project with an attic may include windows built into the roof; this solution provides space big amount light and reduces the cost of installing additional ventilation;

- the room provides space for a staircase, which is made of wood or metal; to save heat, it is often installed directly from the steam room;

- the shape of the roof is used in a broken form in order to make maximum use of the usable space under it; steep side slopes are combined with vertical, strict gables;

- since the room is characterized high humidity and significant temperature changes, it is necessary to provide high-quality thermal insulation and waterproofing in the design of a bathhouse with a 6x4 or 6x8 attic.

Fulfilling these conditions will ensure the most comfortable result.

Modern construction technologies allow to build mobile saunas, which can literally be transported from place to place. Their advantages and operating features can be seen in the video.

VIDEO: The most cheap sauna turnkey transportable mobile saunas made of timber

Compact dimensions 6x4 m

It is generally accepted that a 4x6 bathhouse project with an attic (photo presented below) is the most popular option for implementation in small areas. The building turns out to be compact, but the functionality is not reduced. This footage is enough for a small family to take full advantage of it.

The first floor contains the following rooms:

- steam room;

- shower or washing area;

- pre-bath rest room;

- small veranda.

The veranda area is usually filled with chairs, benches and dining table. This open space creates an atmosphere of simplicity and naturalness. However, it can be sacrificed to expand the useful internal space, increasing one of the built-in rooms.

The attic is used as a bedroom, recreation room or even a storage room. In the latter case, a cozy corner is equipped on the ground floor, combined with the hallway.

During the preparation of projects wooden baths with an attic, the ceiling height in the rooms is 2-2.5 m to ensure comfortable use.

Designing a 6x6 bath

One of the most popular from a practical point of view is the design of a 6x6 bathhouse with an attic made of timber. Thanks to the additional meters of space, a significant increase is achieved usable space. This allows you to expand the room layout options to satisfy all the desires of the bathhouse owners.

In addition to the usual premises for a bath, such as a washing room, steam room or dressing room, in this case you can also place a small pool inside. It is installed as a built-in structure in the floor or as an additional container above the floor level.

The resulting terrace becomes more spacious, which is important for the summer period. If you plan to use the bathhouse frequently in winter, then the terrace can be reduced.

Construction stages

You can independently implement any project from a 6 by 6 bathhouse with an attic to a 6 by 9 bathhouse project with an attic. You just need to stock up on enough materials and choose the right site for construction.

The sequential construction algorithm consists of the following steps:

- The area is cleared and the foundation is installed, which is selected based on the load: either strip or pile-screw.

- The base is covered with a waterproofing coating. To do this, rolls of roofing felt are used, on which the logs of the lower trim are laid. A layer of floor joists is sewn on top of such a durable array. Next, the log house is placed.

- One of the costly items in the design of a bath house with an attic is the installation of metal tiles. A double sheathing with mandatory insulation is formed under it. A double layer of overlapping roofing material is also laid on top.

- The ceiling beams are cut in and the ceiling is installed.

- Wooden log house must be caulked and winnowed from the inside and outside.

- Since in the heating process baths are used open fire, then all wooden elements must be impregnated with several layers of fire-resistant antiseptic. The outside is covered with two layers of façade varnish to protect it from moisture.

- A floating type piping is carried out and, according to the design, bathhouses made of rounded logs with an attic are mounted on their own metal frames.

- The next step is the installation of floors. A layer of expanded clay is often used to insulate them.

- Wooden wall It is enough to sand the inside well and they may not need to be processed anymore.

- At the final stages of implementing the project for a log bathhouse with an attic, the installation of window and door blocks is carried out.

- The steam room is reliably insulated and the ladder is installed in the place prepared for it.

Application of frame technology

There are successful implementations frame projects baths 6x8 m with attic. In this case the role load-bearing structure makes a wooden skeleton from timber. Installation of the racks is carried out on the lower trim at a given equal interval of 0.6-0.8 m.

The selection of timber dimensions for the frame is calculated based on the expected size of the future insulation.

The base drains at the corners are used in the form of 100x100 mm timber, and for intermediate drains it will be sufficient to install 100x50 mm racks. Thermal insulating layer made of modern materials It will be much better to keep the internal temperature of the room in a comfortable range, since the thermal conductivity of such materials is significantly lower than that of wood.

The external cladding of the building is carried out using OSP sheets. This material was developed specifically for such conditions. Popular thermal insulators in such projects of bathhouses with an attic (photos are on the page) are mineral wool and expanded polystyrene. The intermediate gaps between them are filled with polyurethane foam.

With open terrace

Some craftsmen prefer to seal cracks with dry moss, tow or flax. With all the advantages of these natural materials they have a number of significant disadvantages. The first is drying out. Over time, moss and tow dry out and decrease in size, as a result of which drafts begin to penetrate through the cracks and wet air. Second - this is the favorite raw material construction material for birds. Already during the first 5 years they take it away for their own nests, which, of course, also does not add to the tightness of the bathhouse. By the best means modern inter-crown insulation materials are used for sealing cracks, in particular, Polytherm or Consil - latex sealant.

One of the advantages of frame models is a wide selection of exterior decoration. They are covered with siding, all types of tiles, clapboard or block house. External treatment of the frame structure can be carried out immediately, but for a log house you will need to wait 1 year for shrinkage. Even if the bathhouse will be built on pile foundation, you will still need to wait at least 12 months for complete and uniform shrinkage of the entire structure.

VIDEO: Project of a bathhouse with an attic 6x6 m